INTERNANTIONAL TRADE

NDT EQUIPMENT & CONSUMABLES

ROCK is an authorized vendor of Magnaflux and Magwerks products, and we also provide high-quality maintenance and repairs for these products.

Whether you seek parts, equipment, or repairs, you can look to us for support when it comes to Magwerks and Magnaflux non-destructive testing products.

We specialize in a number of varieties of non-destructive testing (or NDT).

These inspections are carried out to detect potential deformations in components without impacting the part or system’s serviceability.

The ROCK team provides full magnetic particle NDT systems, offering AC, HWDC and FWDC output. We also offer the following accessories:

Magnetic Benches

Wet Benches

NDT Benches

AC yokes

LED UV lamps

Penetrants

Shunts

Coils

Magnets

Liquid Penetrant Testing

Liquid penetrant testing uses fluorescent dye to reveal surface flaws on parts and equipment. Thanks to capillary action, which forces liquids to flow into narrow spaces without the influence of gravity, this form of NDT can illuminate flaws that aren’t visible to the naked eye. This makes liquid penetrant testing one of the simplest and cheapest NDT techniques.

Magnaflux offers a full range of penetrant testing products designed to improve testing repeatability. From penetrants and developers to emulsifiers, the Magnaflux line has everything you need to test your equipment. These processes and products are ideal for use with consumables and similar products.

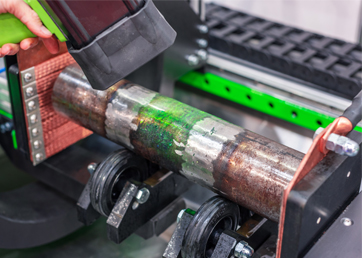

Magnetic Particle Inspection

Magnetic particle inspection allows industry professionals to see surface and subsurface flaws on components made of ferromagnetic materials such as:

Iron

Nickel

Cobalt

Alloys of these metals

The process is simple and quick as it requires no surface preparation.

During magnetic particle inspection, magnetic currents are run through components to locate cracks and other flaws. Metal particles are then spread over the part, which get pulled towards cracks by the magnetic currents, thereby helping determine the size and shape of the flaw.

We offer NDT services using magnetic benches. We also sell these components and calibrate them on request.

UV lamps are used in non-destructive testing to quickly and reliably find indications of component failure. During liquid penetrant inspections, UV lights reveal the light-sensitive particles in the selected fluid. This allows for identification of the nature and extent of any damage cause by the test itself.

Industries Served

NDT inspections are an integral part of the petroleum and petrochemical industries. A number of other sectors, including aerospace, automotive, and defense, also rely on NDT inspections to ensure component safety and functionality. Each of these industries has a common goal: To detect flaws in components in order to reduce failure and increase reliability.

Quality Parts Analysis by ROCK

At ROCK, our team is well equipped to assist you with biannual onsite inspections. During these inspections, our certified staff will help evaluate your equipment for upgrades and offer insight into system and component health. What’s more, when you buy from us, you’re partnering with a factory-trained representative that can offer ongoing support including routine maintenance and calibration year after year.

ROCK is always on track to become a leader in calibration and instrument testing. Our facilities provide our clients with a broad range of services in industries such as:

Automotive

Aerospace

Medical

Computer

Fluid power

Appliances